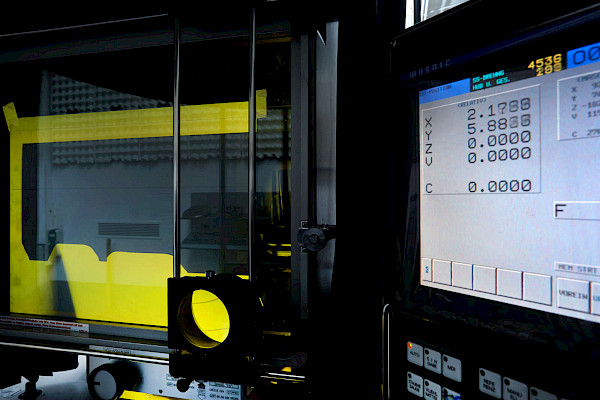

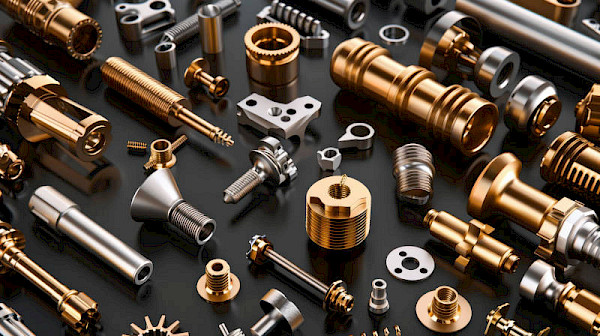

Exceptional know-how and consistent research and development have been hallmarks of Flühs Drehtechnik since 1926. From conventional lathe to CNC control: Flühs Drehtechnik has not just been there for almost 100 years, it has been a trendsetter. A total of 130 CNC and cam-controlled automatic lathes and mechanical lathes are an integral part of the Flühs machine park.

Flühs Blog

More Interesting Insights

Learn more about our values, our commitment to sustainability, and the innovative technologies that shape our company.

Diamond turned parts are manufactured by diamond turning, which produces an exceptionally smooth surface finish. These parts are machined on specialized CNC lathes from materials such as brass, copper, and aluminum. Due to their aesthetic excellence, diamond turned parts are often used as visible trim components that meet exacting design specifications.

Founded in 1926, Flühs has been active in the turned parts industry for nearly a century. Our portfolio includes turned parts and valve technology made from a range of metals, like brass, copper, and stainless steel, all processed at our production site in Lüdenscheid. Stainless steel turned parts are a long-standing element of our product range.

Electroplating is a process for refining metal surfaces with the purpose of improving certain qualities of the metal, such as hardness, corrosion resistance, visual appearance or electrical conductivity.

The electroplating of turned parts contributes to their longevity by increasing their resistance to corrosion or wear.

Copper turned parts are available in various alloy compositions, which offer a wide range of applications, for example in electrical and sanitary applications, but also in mechanical and plant engineering.

Copper turned parts are manufactured using CNC machines, resulting in precisely manufactured, high-quality products that can be produced in any quantity in small and large series.

Since 1926, Flühs has specialized in the versatile material brass and built outstanding expertise in manufacturing high‑quality brass turned parts.

Brass turned parts consist of an alloy of copper and zinc. The ratio between copper and zinc depends on the intended processing and use of the brass turned part.

Simple assemblies consist of non-complex individual components, such as a turned part, which is assembled with a sealing element. Examples include simple valve spindles with o-rings, which are installed by the customer as part of a complete fitting in a specific product.

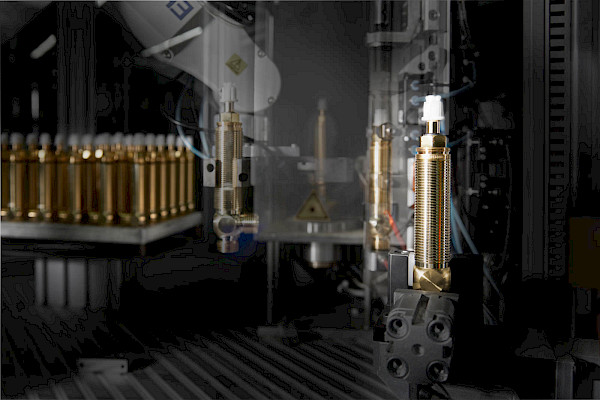

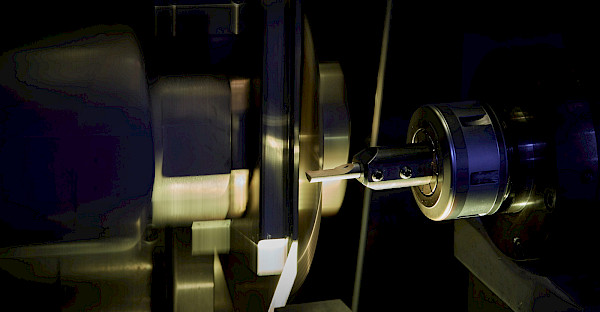

CNC machining is part of modern manufacturing technology, which increases productivity through computer-controlled machines. Flühs operates a machine park consisting of 130 CNC and cam-controlled lathes facilitating a daily output of approximately 1 million machined components.

Flühs offers professional CNC contract manufacturing, supplying CNC turned parts of the highest precision worldwide. CNC contract manufacturing involves outsourcing manufacturing processes to specialized companies that produce components of the highest quality and dimensional accuracy on behalf of their customers.

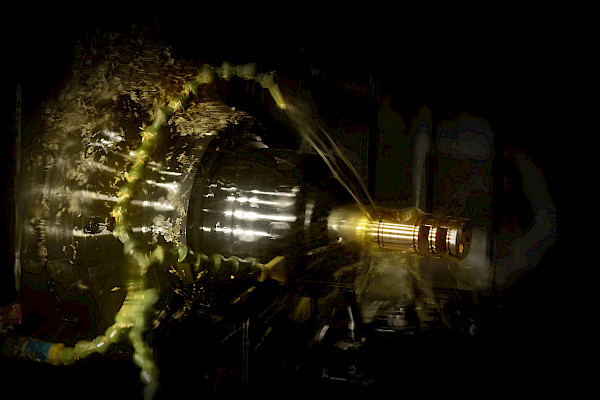

Turning is a very old machining process that is used in many industries today in its various forms. We at Flühs Drehtechnik have been involved in turning for 100 years, since 1926 to be precise. In turning, a workpiece is clamped into an automatic lathe and set in rotation.

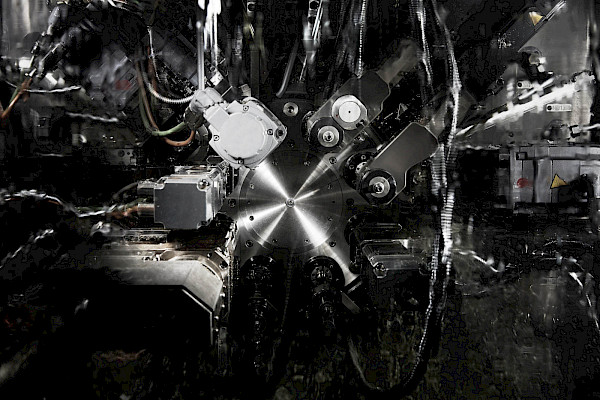

We are specialists in deburring turned parts, as deburring is an integral part of our manufacturing process for high-quality turned parts. Deburring turned parts involves removing burrs, splinters, and chips from the workpiece and smoothing sharp edges.

Annealing turned parts is one of the finishing processes offered by Flühs Drehtechnik. Annealing turned parts complements our extensive range of machining processes, which also includes electroplating, diamond turning and polishing. We work to the highest standards of quality management, based on DIN ISO 9001, VDA 6.1, and ISO TS 16949.

High-quality laser engraving allows turned parts to be marked permanently and precisely. Laser engraving involves engraving a permanent marking into turned parts using a powerful laser beam. Flühs offers precisely manufactured turned parts made from numerous brass alloys that are suitable for laser engraving.

Heating technology is a subfield of building services engineering that deals with the supply of heat to residential, industrial, and commercial buildings. Flühs Drehtechnik manufactures high-quality heating valves and complex assemblies for heating technology. Heating technology encompasses the planning and installation of heating pipes, boilers, radiators, and other systems used to supply heat to a building.

Flühs has been producing small turned parts for 100 years and has developed into a market leader in the fitting and sanitary industry. We produce all types of small turned parts in sizes starting at a bar diameter of 6 mm. We manufacture small turned parts from various metals.

Flühs has been dedicated to the manufacture of all types of turned parts for 100 years. Our standard products include components for valve and system technology. Among other things, we use plastics for certain spare parts in our cartridges and valves.

Flühs has been manufacturing high-quality long turned parts in small to large series since 1926. We have been manufacturing all types of long turned parts for 100 years. In addition to manufacturing long turned parts, we also specialize in short turned parts and diamond turned parts, among other things. A long turned part has a ratio of at least 3:1 between length and diameter.

The mixing valve is a frequently requested product at Flühs Drehtechnik, which ensures a consistent temperature at the outlet of the respective fitting by mixing cold and hot water and providing precise temperature control.

Flühs manufactures high-quality precision turned parts, which are available in small, medium, and large series. Flühs produces all types of precision turned parts for sanitary and building services applications. We have been operating as a turned parts manufacturer since 1926. Due to their complex geometry and small diameters, precision turned parts are manufactured using CNC machines and are used, for example, in valve technology, sensor and measuring devices, and in numerous industries.

Sanitary engineering encompasses everyday technical installations such as kitchen and bathroom fittings and forms the basis for reliable water supply and wastewater disposal. Flühs Drehtechnik is a leading system supplier to the sanitary industry, specializing in valve technology in particular.

Plumbing valves from Flühs are high-quality products, which are based on about 100 years of experience. Flühs is a manufacturer specializing in sanitary engineering and valve technology that exports to more than 50 countries around the world.

Drinking water installations are installed in buildings to supply cold and hot water. Flühs is a manufacturer specializing in sanitary and building services applications that produces all types of valves for drinking water installations. Drinking water installations include fittings, valves, pipes, and hot water treatment systems, which serve to provide hygienically safe drinking water.

Machining encompasses all manufacturing processes in which material is gradually removed from the surface of a workpiece using tools (such as cutting tools or grinding machines). Since 1926, we at Flühs have specialised in manufacturing customized components using turning machining technology.