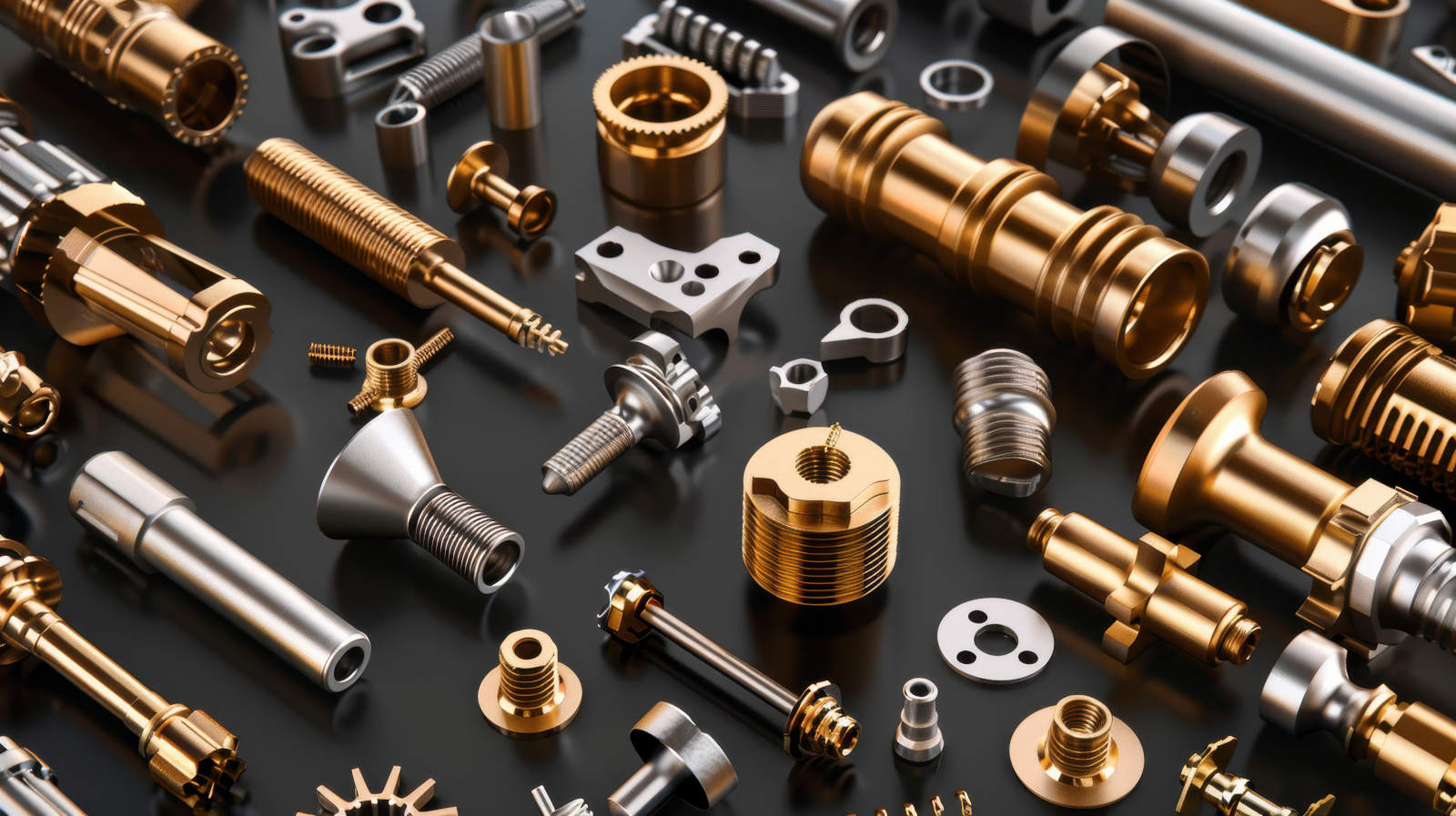

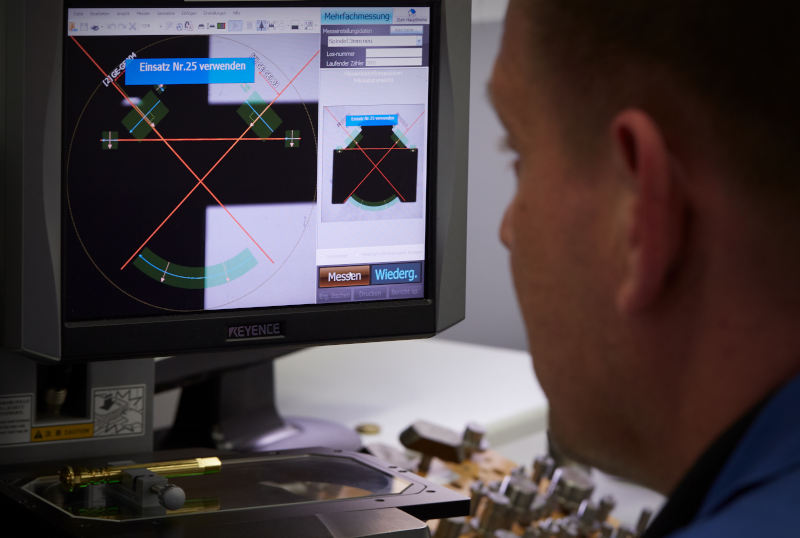

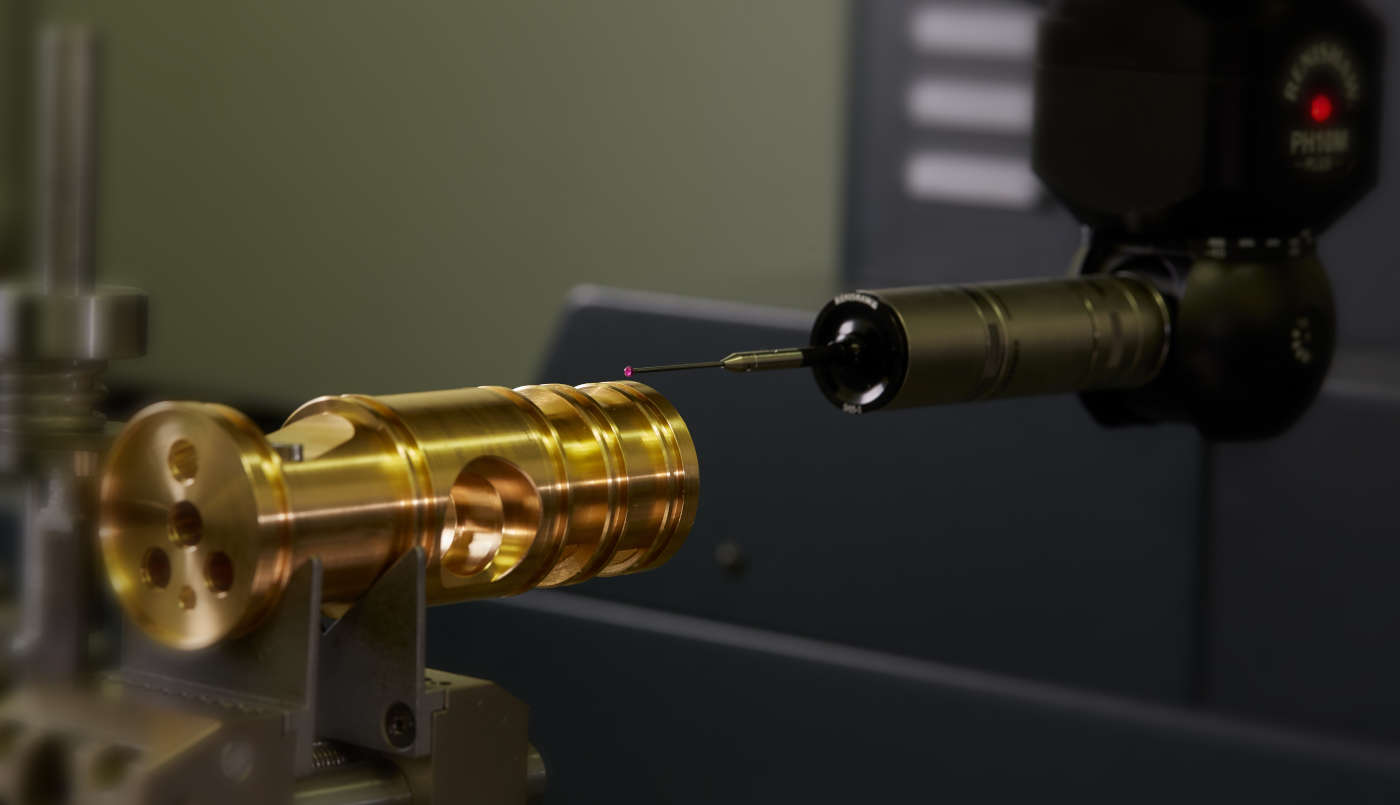

You should choose products from Flühs Drehtechnik because they meet the highest quality standards and market requirements and have a long service life thanks to strict quality controls and the use of high-quality materials. Flühs manufactures turned parts and valves in any quantity and individually according to the customer's requirements and ideas.

We source our materials, such as brass and copper as well as other alloys, from first-class suppliers with whom we have a long-standing working relationship. Innovation is another important aspect of our success. Over 200 patents are the result of our efforts to create innovative products.

In addition to their durability, our valves are characterized by particularly smooth operation and ease of use. We manufacture our products in different variations depending on customer wishes and market requirements (for example, in different sizes, alloys and variants depending on country-specific requirements). All product groups can be customized.