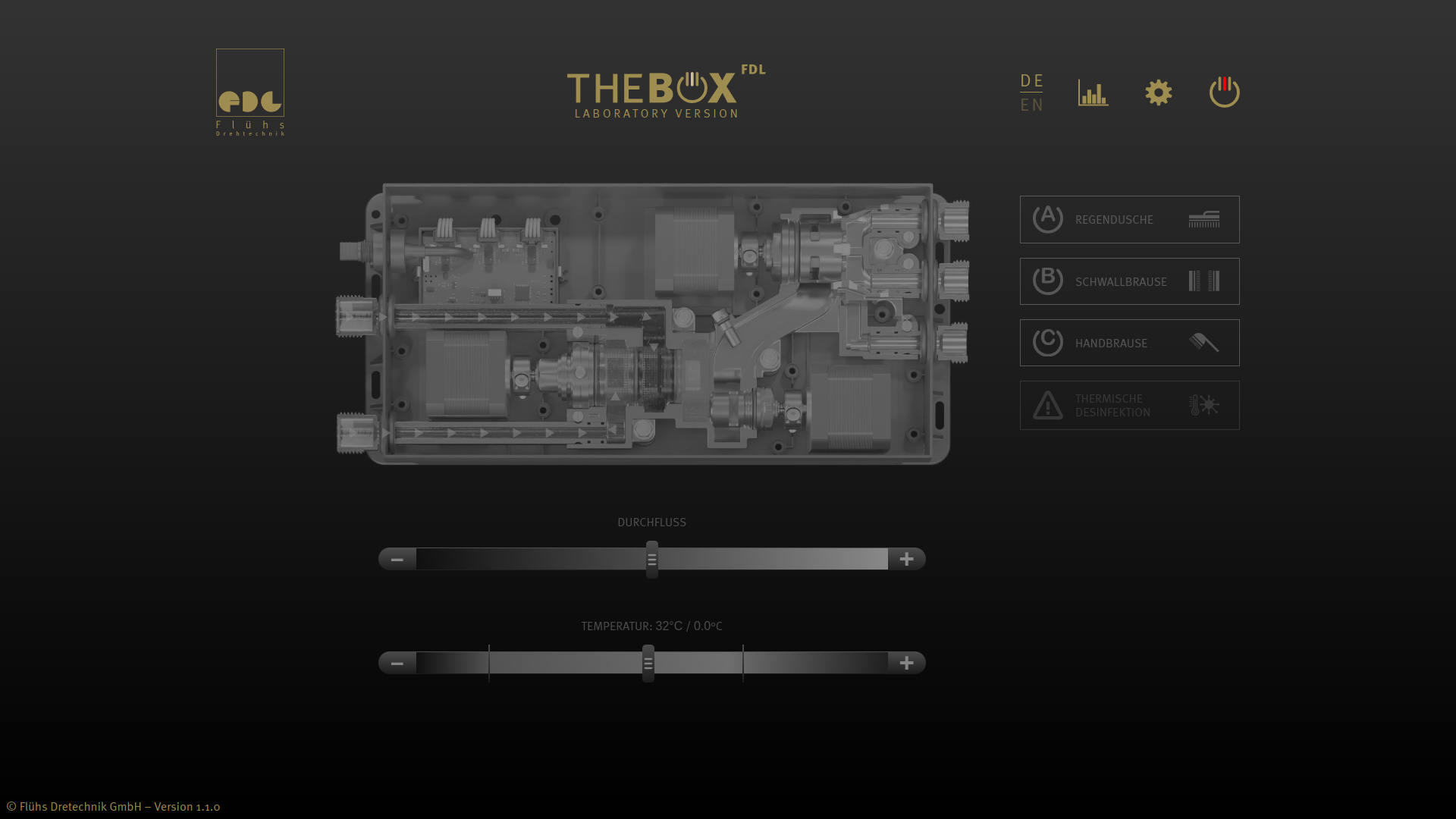

Systems engineering is an interdisciplinary field of engineering and engineering management that designs and optimizes complex structures and technical systems so that all individual modules or subsystems contribute to the overall system’s performance.

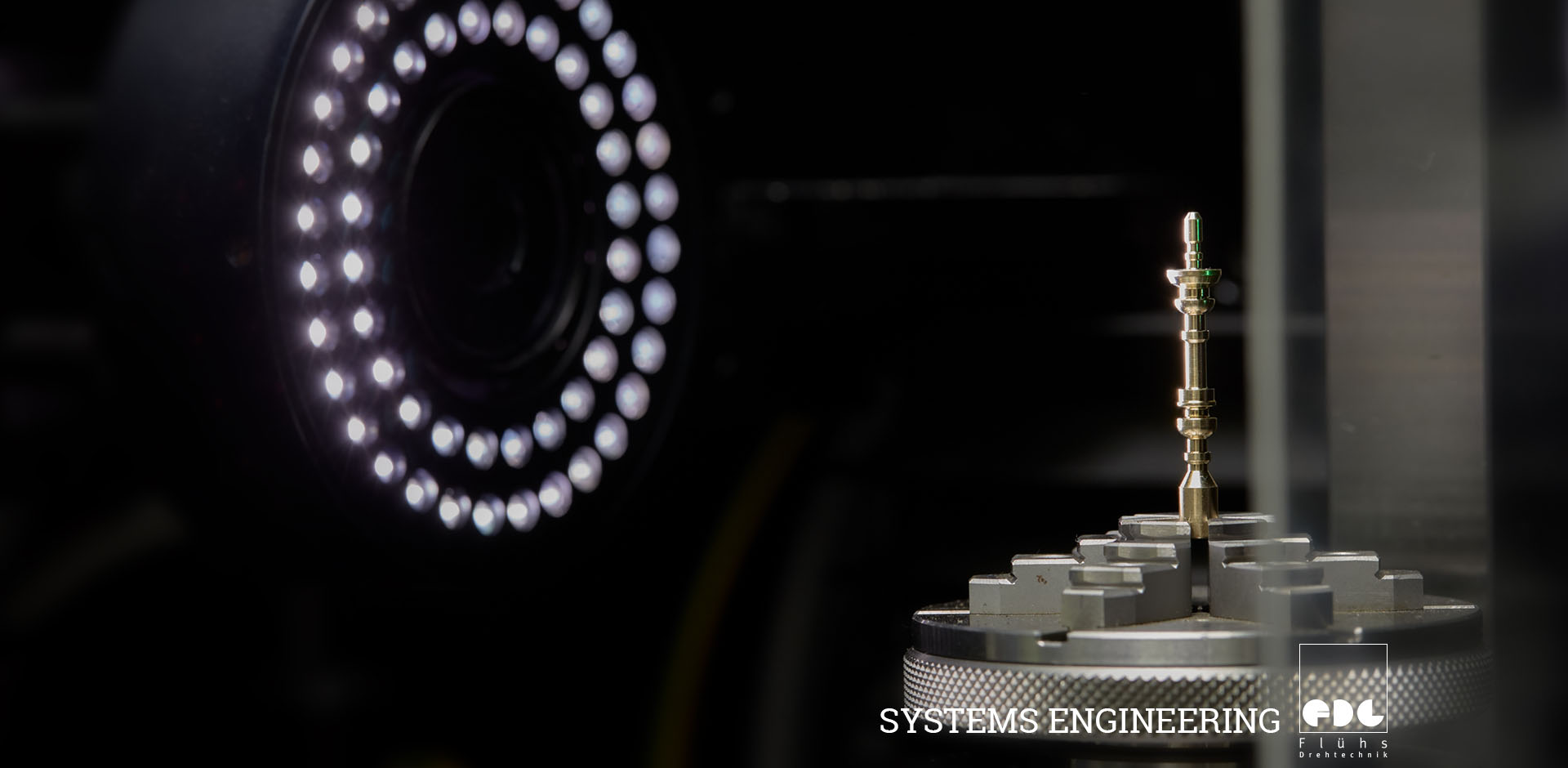

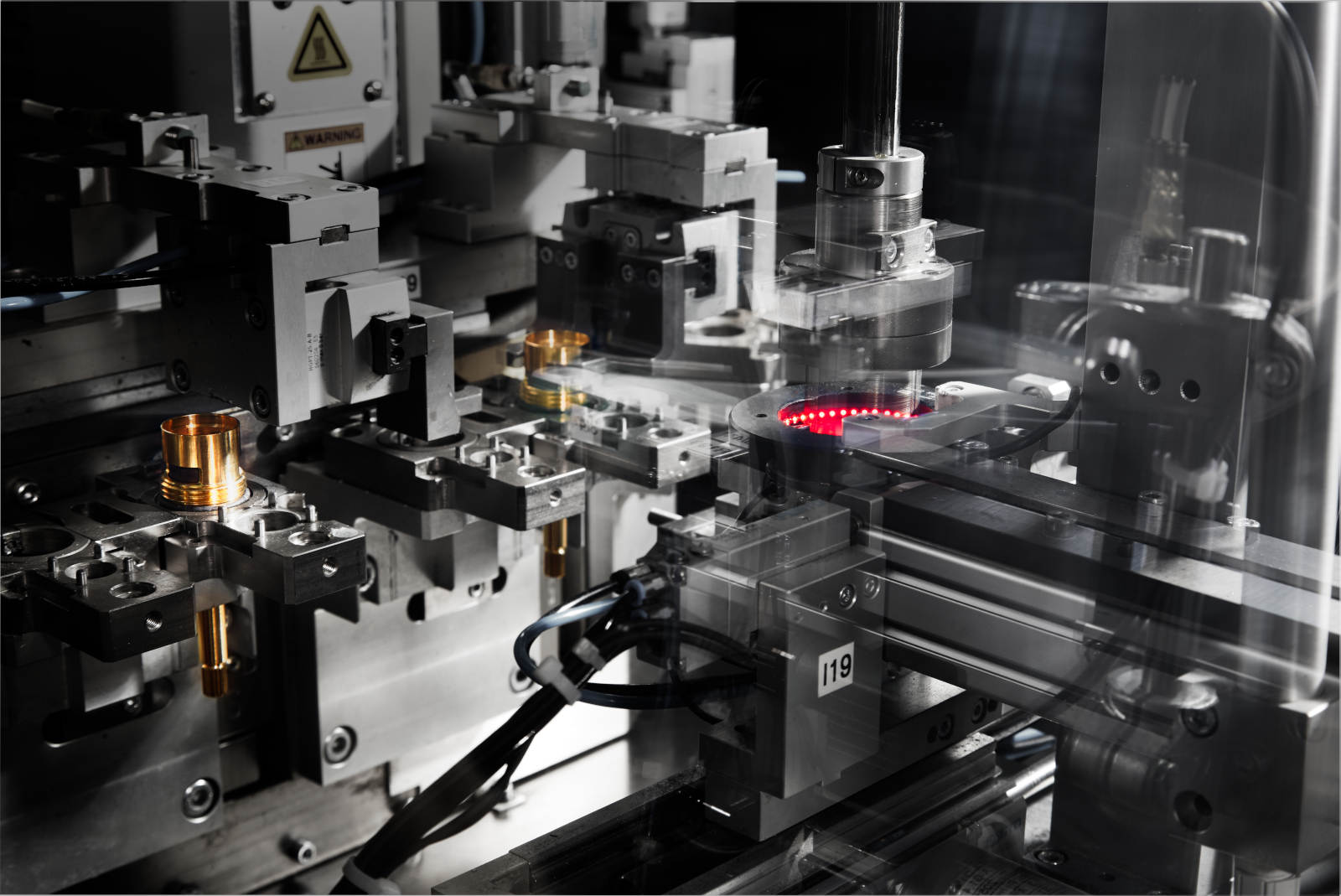

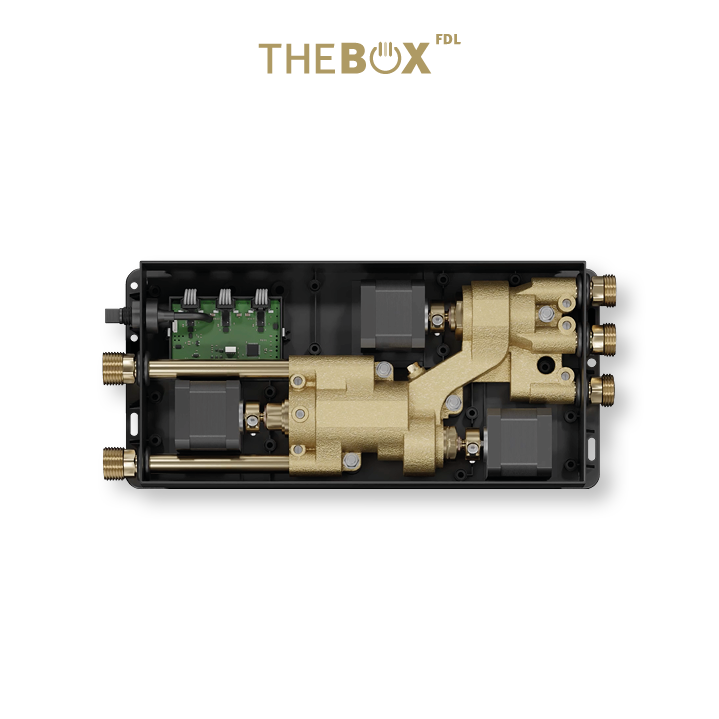

A system in systems engineering is a group of elements that interact to achieve a specific objective or to ensure a defined function. A practical example are turned parts integrated into complex machinery: the machine’s functionality depends on each turned part operating smoothly and interacting correctly with other components. Accordingly, systems engineering focuses on the interaction between assemblies and subsystems. For a system to function, every element must reliably fulfill its intended role. Multiple elements form a component, which, together with other components, becomes part of an assembly.

Systems engineering also considers the entire lifecycle of a system and its assemblies: conception, use, and decommissioning. Before producing a turned part, for example, it is crucial to know the application context, the operating conditions, and the minimum service life it must be designed to achieve.

Contact us