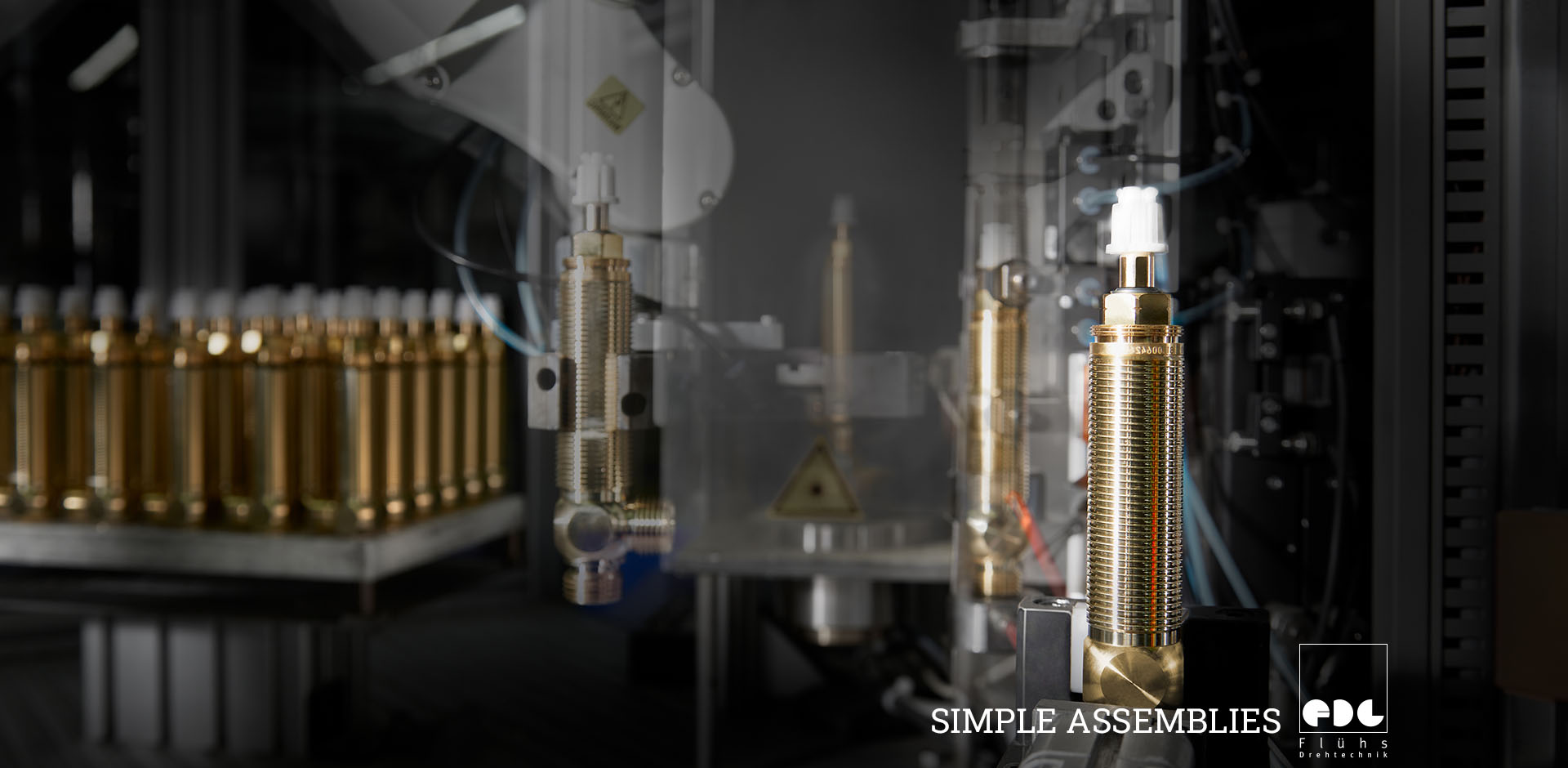

Simple assemblies are composed of several individual parts, such as a turned part and a sealing element, which belong to the same assembly level.

A simple assembly consists of individual parts that are installed in a component and perform a specific technical function. For example, a turned part and a sealing element combine to form a valve component that is used to shut off the pipeline.

There are no hierarchical categorizations for simple assemblies. They do not have any subassemblies that themselves consist of individual components, as is the case, for example, with a fitting as the main assembly with the valve headwork and valve body as subassemblies. Simple assemblies form a single component from individual parts. For example, the spindle body and o-ring form a valve spindle, which in turn is a component of the valve headwork. Simple assemblies are generally standardized, easy to install, easily replaceable, and maintenance-friendly. They are easy to assemble and consist of relatively few complex components, such as turned parts and sealing rings, valve cones and sealing washers, or valve seats and o-rings.

There are various examples of simple assemblies in valve technology, which are described in the following section.