CNC Machining | Flühs

CNC machining is part of modern manufacturing technology, which increases productivity through computer-controlled machines. Flühs operates a machine park consisting of 130 CNC and cam-controlled lathes facilitating a daily output of approximately 1 million machined components.

We perform CNC machining with lathes that produce complex turned parts, precision turned parts, and long turned parts in small, medium, and large series. Flühs Drehtechnik has been active in the turned parts industry for almost 100 years and has been supplying OEMs in the sanitary and building services engineering as well as the automotive sector for decades.

CNC (computerized numerical control) machining enables the economical and precise processing of various materials (including metals, non-ferrous metals, and plastics). The tools are controlled by a computer integrated into the CNC machine.

The advantages of CNC machining lie in its cost-effectiveness, precision, and consistently high quality. CNC machines are programmed on the basis of CAD files and reliably adhere to the specified dimensions.

Tools frequently used in CNC machining include milling cutters, drilling tools, thread cutters, turning tools, and cutting tools, which are controlled using the programming code (G-code) generated from the CAD files.

This text deals with the basics of CNC machining, discusses its advantages, and describes the most common tools used in CNC machining.

What is CNC machining?

CNC (computerized numerical control) machining is a subtractive manufacturing process used to produce components from aluminum, copper, steel, plastics, and composites.

There are various CNC machining processes, including CNC turning, CNC milling, and CNC drilling.

CNC turning is an automated manufacturing process based on the machining of a rotating workpiece to produce rotationally symmetrical components, such as precision turned parts. CNC lathes can be used to produce components such as axles, shafts, screws, and nuts in large quantities with consistent quality.

CNC milling is a computer-controlled machining process in which a workpiece is cut using computer-controlled multi-point cutting tools. A rotating milling cutter is used to continuously remove material from the surface. Depending on the type of machine, either the tool, the workpiece, or both move. CNC milled parts are used in mechanical engineering, aerospace technology, and construction, among other areas.

CNC drilling is a subtractive, computer-controlled manufacturing process in which rotating drilling tools are used to make precise bores in materials such as metal, wood, or plastic. The process is based on G-code programs derived from CAD data. The control system precisely defines parameters such as drilling depth, speed, and feed rate. CNC drilling is often used as a sub-process in CNC milling or CNC turning.

CNC manufacturing processes

Despite the different manufacturing processes, the main steps of CNC machining are largely the same. CNC machining essentially comprises 4 steps: CAD model creation, CAD file conversion, CNC machine setup, and the machining process.

-

CAD model creation

CAD (computer-aided design) is a computer-based technology for creating 3D models and 2D drawings for objects and systems, such as technical components. Designers and engineers use CAD software to model components in the correct dimensions and shapes according to customer specifications.

-

Conversion of CAD files

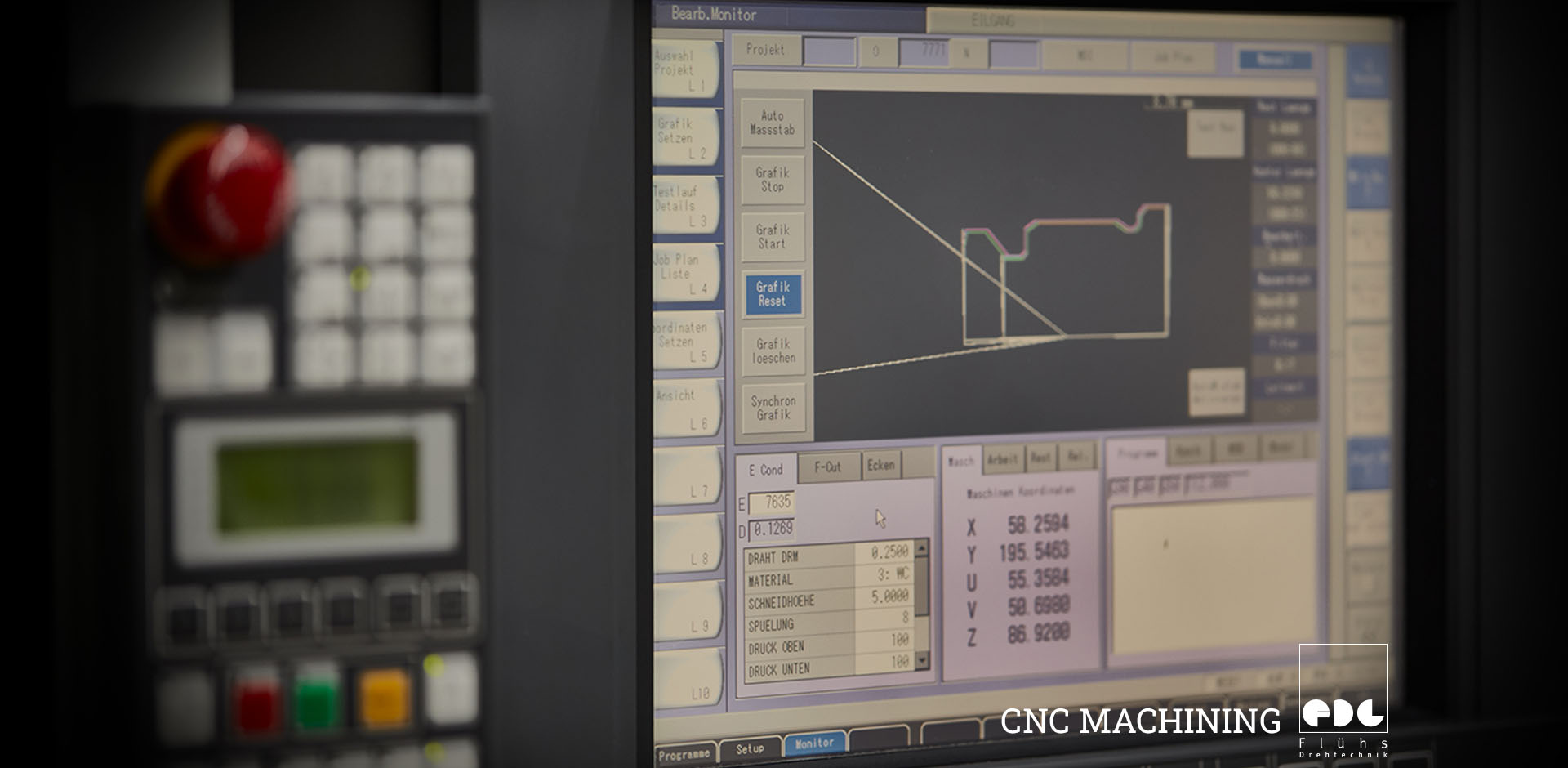

The CAD files are converted to generate a programming code. This programming code is used to direct the movements of the CNC machine. These are mostly G-code commands. G-code is a standardized programming language for programming CNC machines and 3D printers that lists instructions for the machine or printer.

-

CNC machine set up

After the CAD files have been converted, the program code is loaded onto the CNC machine. The workpiece is then inserted into the machine either manually or automatically.

-

Machining process

The CNC program code provides work instructions for the computerized control system of the CNC machine, which operates and controls the machining tool.

CNC machining has a number of qualitative and cost-related advantages in the machining process, which are described below.

What are the advantages of CNC machining?

The advantages of CNC machining are its high precision and accuracy due to automation, increased turnover with reduced personnel costs, its versatility, integration into digital production processes, faster production times, and repeatability.

One of the biggest advantages of CNC machining is its increased precision and accuracy compared to conventional machining. CNC machines can handle tight tolerances. Through automated, computer-controlled machining, CNC machines ensure all components have the necessary fit accuracy for assembly.

CNC machining leads to an increased turnover because it can be implemented 24/7, requires minimal supervision, and delivers continuous output. CNC machines enable a very economical production, especially for large quantities.

One advantage of CNC machining is that it is a versatile machining process that can be used with a wide range of materials. CNC machines process metallic materials such as titanium, aluminum, or steel, as well as plastics such as POM (polyoxymethylene) or PE (polyethylene). This makes CNC machining a relevant factor in the manufacturing process for many different industries.

CNC machining enables a high degree of repeat accuracy. Once the CNC machine has been programmed, it is possible to produce the same part in any quantity without any deviation in quality.

CNC Machining at Flühs

CNC machining at Flühs is carried out using state-of-the-art CNC lathes.

Our CNC lathes are used to manufacture long turned parts, precision turned parts, and complex turned parts in small, medium, and large series, among other things. A key area of application is the manufacture of our wide range of valves, for which we produce turned parts in-house on our CNC lathes.

Our CNC lathes are equipped with automatic loading magazines that feed the bar stock. The workpiece is then clamped in place and set in rotation. Depending on the machine type, machining is performed either via a tool slide or via one or more tool turrets. In the tool slide design, the tools are permanently mounted and move linearly along the rotating workpiece. The rotary tool turret allows quick changes between multiple tools, thus increasing flexibility and productivity. In both cases, the chips are precisely removed until the required geometry with dimensional accuracy is achieved.

The final inspection is automated using glass slides and image processing systems such as high-speed cameras. The image processing systems check whether the turned parts correspond to the specified dimensions and sort out parts with deviations.

Thanks to CNC machining, Flühs Drehtechnik is able to produce around 1 million turned parts every day.

What tools are used in CNC machining?

CNC machining uses tools such as cutting, milling, turning, drilling, and grinding tools, such as end mills, twist drills, or thread turning tools.

The tools are computer-controlled in CNC machining. In addition to tool movements, the CNC machine also controls spindle speed, feed rate, coolant supply, and the monitoring of process parameters. Different tools are used in CNC machining depending on the machining process.

Milling tools such as end mills, face mills, and disc mills are used in CNC machining to remove material from the workpiece surface. Milling tools are versatile. Among other things, they are suitable for producing profiles, grooves, and threads, as well as for smoothing or planing surfaces.

In CNC machining, drilling tools such as twist drills, core drills, and center drills are used to make bores. Typical applications for CNC drills include drill bores for screws, threaded holes, and deep hole boring in toolmaking.

Turning tools such as thread turning tools, cut-off tools, or internal turning tools are used in CNC machining to produce rotationally symmetrical components. CNC turning tools are used, for example, to produce locking grooves, sealing surfaces, screws, spindles, and for cutting off bar stock.