Plastic Turned Parts from the Manufacturer | Flühs Drehtechnik

High-quality plastic turned parts are used in a wide range of industries, including medical technology, building technology, and the automotive industry. At Flühs, we have specialized in the manufacture of turned parts from a wide variety of materials such as brass, stainless steel, and red brass since 1926.

Flühs has been dedicated to the manufacture of all types of turned parts for 100 years. Our standard products include components for valve and system technology. Among other things, we use plastics for certain spare parts in our cartridges and valves.

If you have any questions about our turned parts, please contact info@fluehs.de or call us on +49 2351 975-0.

Plastic turned parts are used as seals, fittings, or control components in many industries, including water technology, the automotive industry, medical technology, and building technology.

There are several material options for the manufacture of plastic turned parts; thermoplastics, thermosets, and elastomers are particularly commonly used. During processing, the specific deformation behavior and thermal properties of the various plastics are to be taken into account.

In the following, we discuss the different types of plastic turned parts, how they are manufactured, and their advantages and disadvantages.

Plastic Turned Parts

Plastic turned parts are components manufactured on lathes, for example, from polyamide (PA), polyoxymethylene (POM) or polyethylene terephthalate (PET). Plastic turned parts are used in various industries as nozzles, spindles, bushings, or sealing elements.

Several types of plastic can be used to manufacture plastic turned parts. In general, plastics can be divided into 3 categories in an industrial context: standard thermoplastics, engineering plastics, and high-performance plastics.

Standard thermoplastics are plastics such as polyethylene (PE) or polypropylene (PP), which are inexpensive and easy to mold. They are suitable for the production of plastic turned parts that are not exposed to particularly high temperatures or aggressive chemicals. Thermoplastics can be processed in all industrial processes and, to a certain extent, it is possible to improve certain material properties, such as their chemical resistance, by adding additives.

Engineering plastics, such as polyamide (PA), polyethylene terephthalate (PET), or polyoxymethylene (POM), offer higher performance than standard thermoplastics in terms of heat resistance, chemical resistance, and mechanical strength. Plastic turned parts made from engineering plastics are therefore more durable and robust.

Plastic turned parts made from high-performance plastics, such as polyetheretherketone (PEEK) or polyimide (PI), have particularly high temperature resistance, mechanical strength, and chemical resistance. High-performance plastics are suitable for long-term use at high temperatures of over 150°C, with some types of plastic even withstanding temperatures of up to 500°C for short periods.

Within these groups, consisting of standard thermoplastics, engineering plastics, and high-performance plastics, there are different types of plastic turned parts, which are explained below.

What types of plastic turned parts exist?

There are various types of plastic turned parts made from elastomers, thermosets, or thermoplastics.

A large number of plastic turned parts are made from thermoplastics. Most engineering plastics and high-performance plastics belong to the thermoplastics group. Thermoplastics are plastics that can be deformed within a certain temperature range (between 100 and 150°C, depending on the variant) and become solid again when cooled. This process is repeatable as often as desired with thermoplastics, as they can be remelted. Engineering thermoplastics are plastics that can be used at higher temperatures of up to 150°C. Examples of corresponding plastic turned parts include valve housings, bearing bushes, and fittings made of polyoxymethylene (POM), polyethylene terephthalate (PET), and polypropylene (PP).

Plastic turned parts based on thermosets are often used in electrical engineering and mechanical engineering. Thermosets include, for example, phenol formaldehyde (PF) and epoxy resins (EP). Thermosets, also known as duromers, are plastics that solidify after heating and can no longer be deformed. Unlike thermoplastics, thermosets cannot be remelted once they have hardened. Examples of plastic turned parts made from thermosets include pump components, slide valves, and spiral housings for pumps.

A few plastic turned parts are made from elastomers. Elastomers are used, for example, in sealing rings and in piston and rod seals. Like thermosets, elastomers cannot be remelted after curing. An exception to this are thermoplastic elastomers (TPE), which behave like classic elastomers at room temperature but can be reshaped when heated.

Which plastic turned parts does Flühs manufacture?

Flühs does not generally manufacture plastic turned parts, as we specialize primarily in valve and system technology using easy-to-machine and durable brass alloys, which are widely used in sanitary and building services applications worldwide.

The production of plastic turned parts is very complex and, compared to metal, poses different challenges, for example in terms of formability and cooling during the machining process. As our resources are mainly tied up in the field of metal cutting, we do not currently manufacture plastic turned parts in series.

There is a wide range of plastics available for the production of plastic turned parts. Over 200 types of plastic are used in a wide variety of environments. They have unique advantages, but also disadvantages.

What are the advantages and disadvantages of plastic turned parts?

The advantages and disadvantages of plastic turned parts are, above all, their low weight, low price, and versatile processing on the one hand, and their easy deformability at high temperatures and difficult disposal on the other.

A unique advantage of plastic turned parts is that they do not corrode. This opens up a wide range of applications, both outdoors and indoors. The addition of other additives can optimize properties such as UV resistance.

Another major advantage of plastic turned parts is their low weight due to the low density of plastic. They are also very inexpensive to produce. Plastic turned parts have the disadvantage of deforming at high temperatures.

Certain additives improve temperature tolerance, with the maximum often being around 100°C.

Another disadvantage of plastic turned parts is that the most common plastics are petroleum-based. Petroleum is a limited resource. Plastic is difficult to dispose of, as most types of plastic take a very long time to decompose.

How are plastic turned parts manufactured?

Plastic turned parts are manufactured using a turning machine. CNC and cam-controlled lathes rotate clamped plastic rods and use cutting and forming tools to machine them into the desired shape.

The use of CNC machines for the production of plastic turned parts ensures the necessary precision and accuracy in manufacturing. This allows products to be manufactured in small to very large quantities with the highest quality.

The production of plastic turned parts has a number of special features, including the specific thermal properties of the material and the presence of residual stresses.

When turning plastic turned parts, the special thermal properties of the material must be taken into account, including its easy deformability. The coefficient of thermal expansion for many types of plastic is up to 20 times greater than that of most metals. During the turning process, heat is generated by friction between the tool and the workpiece. However, cooling lubricants are not permitted in connection with most high-performance plastics, so the design of the turned part and the equipment of the CNC machine are to be adapted accordingly. For example, compressed air can be used as a coolant to cool the tool.

Another specific feature of plastic processing is the residual stress in the plastic. The residual stress is released during machining, which affects the accuracy of the end product, for example by causing deformation. It therefore makes sense to reduce the residual stresses in the plastic before the manufacturing process, for example by using temperature ovens.

With the help of CNC machines and by taking into account the special properties of the material, a high degree of accuracy can be achieved despite the challenges, making it possible to manufacture customized plastic turned parts without any problems.

Customized Plastic Turned Parts in Small, Medium, and Large series

Customized plastic turned parts in small, medium, and large series can be manufactured economically with CNC machines.

Prior to the production process, a comprehensive consultation takes place, during which the material is selected and the customer-specific requirements for the respective plastic turned part are clarified. Our own research and development (R&D) department works closely with our customers to develop individual, tailor-made solutions.

The same tolerances cannot always be applied to the manufacture of plastic turned parts as to metal turned parts, as the processing of plastics is very demanding.

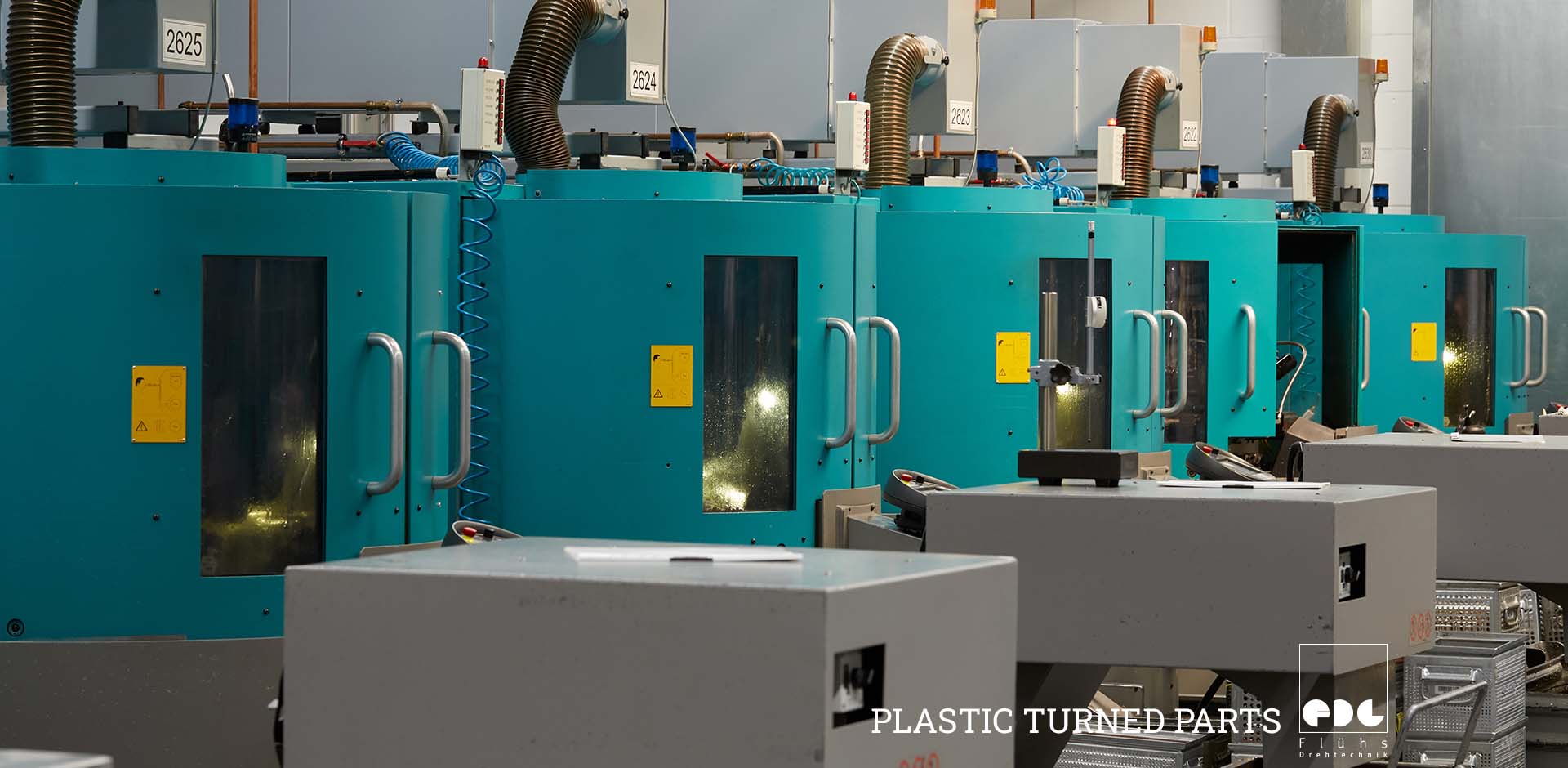

Plastic turned parts are manufactured using CNC machines, which enable the required dimensions and tolerances to be achieved in high volumes for series production. Our machine park comprises approximately 130 CNC and cam-controlled lathes. This enables us to produce turned parts from metals in small, medium, and large series flexibly and economically.

About Us

Flühs offers a wide range of turned parts designed for demanding technical environments. With 100 years of experience in turning since our founding in 1926, we have developed exceptional expertise in this complex industrial process. Today, we manufacture high-quality turned parts for valve and system technology. We use plastics for certain spare parts in our cartridges and valves.

Our recipe for success remains unchanged: high-quality materials, precise state-of-the-art manufacturing processes and an in-house quality management system based on DIN ISO 9001 and ISO 14001. Over 200 patents are the result of our power to innovate, which has been with us for around a century. Flühs is a recognized training company for technical professions with diverse specializations.