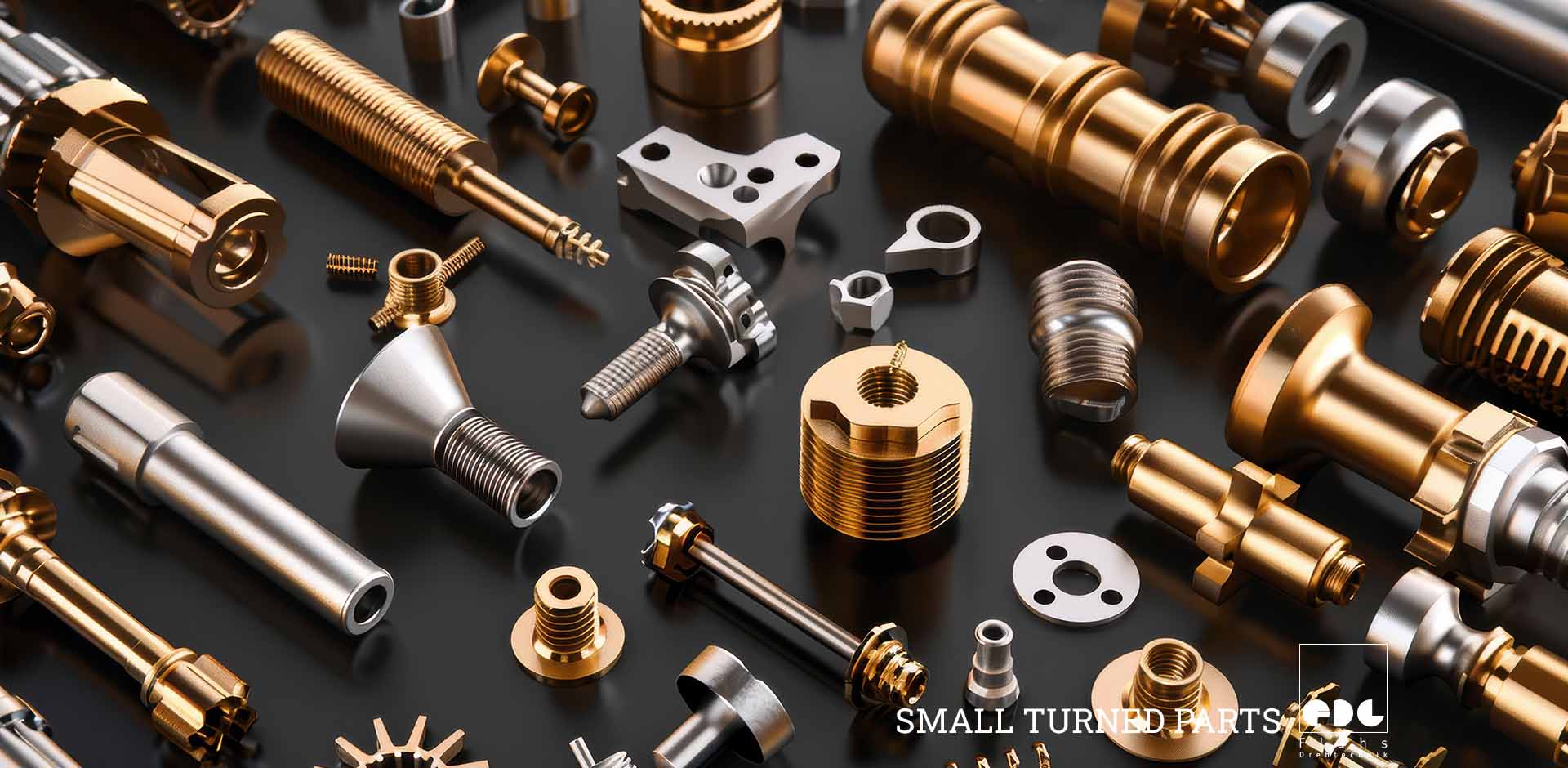

The range of applications of small turned parts include electrical engineering, the watch industry, medical technology, mechanical engineering, and valve technology, where they are used in the form of bushings, drive shafts, implant components, or connecting elements.

In medical technology, small turned parts have particularly fine surface finishes, as hygiene and biocompatibility are paramount. Small turned parts in medical technology include bone or dental screws, turned parts in injection systems, and drill components in dental technology.

In electrical engineering, small turned parts are installed in cell phones, microphones, sensors, and cameras to support reliable electrical connections.

Small turned parts are often used in valve technology, such as spindles for transmitting the drive force to the sealing element or union nuts for fixing components or connecting them to each other.

Flühs is an experienced valve manufacturer that relies on the processing of its own turned parts, which ensure the smooth functionality of all of our approximately 1,400 active valve groups.