Stainless Steel Turned Parts from the Manufacturer | Flühs Steel Turned Parts

Flühs is a reliable manufacturer of high‑quality stainless steel turned parts used worldwide.

Founded in 1926, Flühs has been active in the turned parts industry for nearly a century. Our portfolio includes turned parts and valve technology made from a range of metals, like brass, copper, and stainless steel, all processed at our production site in Lüdenscheid.

Stainless steel turned parts are a long-standing element of our product range.

If you have any questions, please contact info@fluehs.de or call us on +49 2351 975-0.

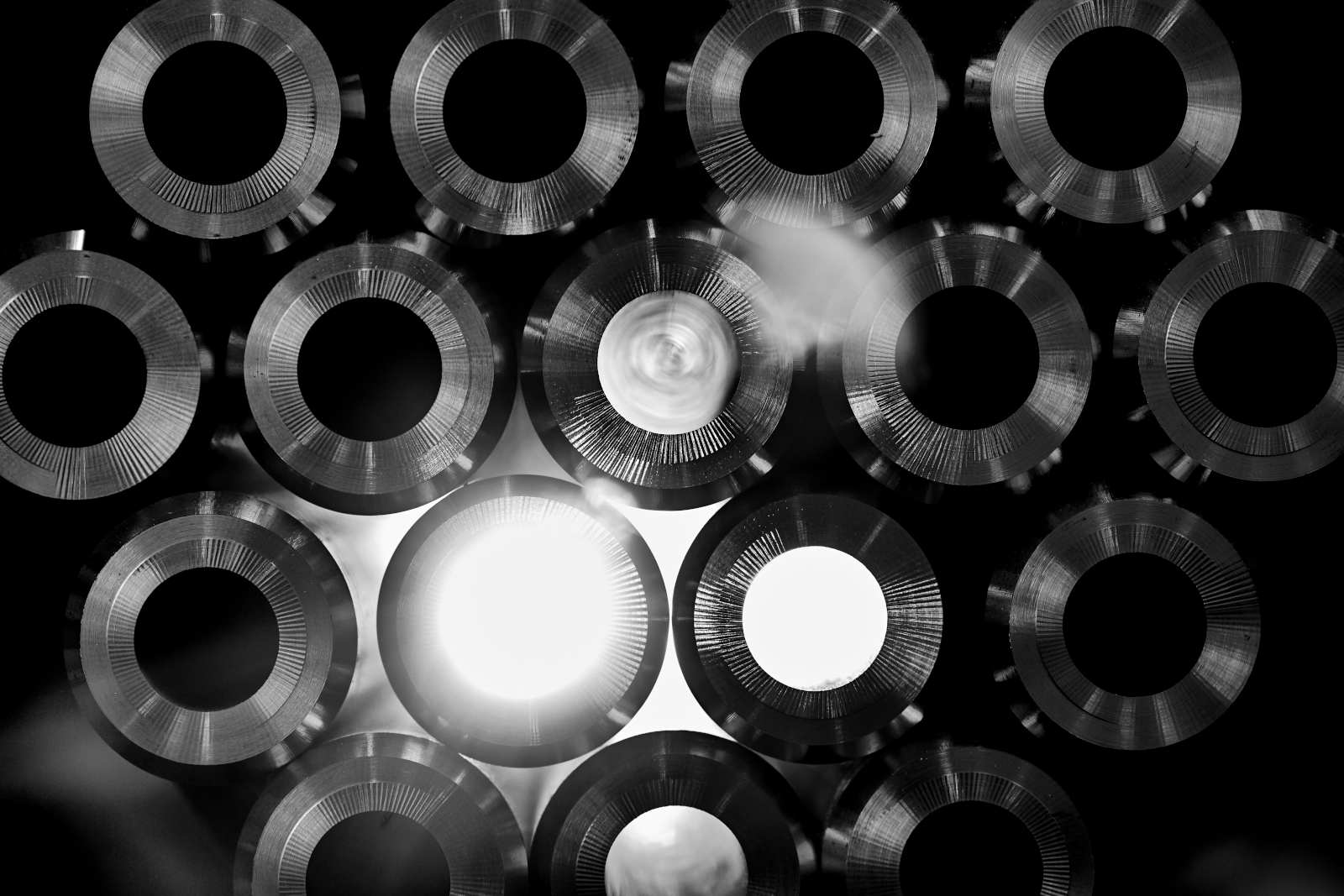

Stainless steel turned parts are produced on CNC lathes and are renowned for their high corrosion resistance, durability, and a smooth, shiny surface.

Stainless steel grades differ in alloy composition based on the intended application. Key drivers are chromium and nickel contents, which determine corrosion resistance and strength. Some grades include sulfur to improve machinability. This benefit comes at the cost of reduced corrosion resistance.

This text outlines the main types of stainless steel turned parts, their advantages and disadvantages, and how they are manufactured.

Stainless Steel Turned Parts

Stainless steel turned parts, for example valve components, are made from metal that is formed using a lathe. They are used across many industries (automotive, machinery, plumbing and building services) thanks to their long service life, corrosion resistance, and high‑quality appearance.

In everyday usage, stainless steel is also called “rust‑free” or “non‑rusting” steel. Technically, the term “stainless” refers to particularly clean steels, independent of corrosion resistance. According to EN 10088, stainless steels contain ≥ 10.5% chromium and < 1.2% carbon. As carbon content rises, steel hardness increases. Stainless steel turned parts are frequently made from Cr‑Ni alloys, with material no. 1.4301 (AISI 304) being especially common.

Under DIN EN 10027‑2, material numbers encode the main material group, steel subgroup, sequential number, steelmaking process, and condition. Both unalloyed and alloyed stainless steels form their own steel groups and are widely used across industries, each offering distinct properties.

What types of stainless steel turned parts exist?

There are various types of stainless steel turned parts, which differ depending on their alloying elements, such as chrome steel, chrome-nickel steel or high-alloy special steels with cobalt.

There are basically 4 different types of stainless steel. These are austenitic, martensitic, ferritic and austenitic-ferritic (duplex stainless steels). There are also heat-resistant stainless steels as a special group.

Stainless steel turned parts made of martensitic stainless steel (group C1, C3, C4) are used, for example, as piston rods, surgical instruments or shafts. Martensitic steels contain at least 0.1% carbon, 12-18% chromium and a maximum of 3% nickel and can be hardened by heat treatment.

Stainless steel turned parts made of ferritic steel (group F1), so-called chromium steels, are used when magnetizability and relatively high strength are required, for instance, for magnetic closures or sensor devices. Ferritic steel consists of a maximum of 0.1% carbon, 12-19% chromium and a maximum of 3% nickel.

Stainless steel turned parts made of austenitic steel (groups A1, A2, A3, A4, A5) consist of chromium-nickel or chromium-nickel-molybdenum steels and are often used as valve spindles, screws, nuts or sleeves. They contain at least 17-20% chromium, 8%-12% nickel and low carbon content. This steel group has outstanding corrosion resistance, although they are not hardenable. Due to their high ductility, these steels are easy to cold form.

A common hybrid form between austenitic and ferritic stainless steel is the so-called duplex steel. Duplex stainless steel combines the microstructures of austenitic and ferritic steels and it combines their advantages: high strength, good toughness and improved resistance to stress corrosion cracking. Stainless steel turned parts made of duplex stainless steel are characterized by superior mechanical properties, especially in terms of strength.

Heat-resistant stainless steels have a high chromium and nickel content and were developed for the application range between approx. 600 and 1000°C. They are characterized by high resistance to oxidation and scaling under thermal stress.

Which stainless steel turned parts does Flühs manufacture?

Flühs manufactures stainless steel turned parts that can be used in sanitary fittings and are highly resistant to wear and corrosion. We mainly use austenitic chromium-nickel and chromium-nickel-molybdenum steels.

A frequently used material for stainless steel turned parts is X2CrNiMo17-12-2 (material number 1.4404, also known as AISI 316L). It is one of the most common stainless steels with approx. 17% chromium, 12% nickel and 2-2.5% molybdenum as well as a reduced carbon content (<=0.03%). This material therefore has improved corrosion resistance, even against media containing chloride, and very good processing properties.

Numerous stainless steel turned parts are also made from chrome-nickel steel. One example of this is X5CrNi18-10 (material number 1.4301, also known as AISI 304). This is an austenitic steel with excellent corrosion resistance. This material is recommended when high demands are placed on processing properties, corrosion resistance and aesthetics. It consists of 17.5-19.5% chromium and 8.0-10.5% nickel.

Another relevant material for stainless steel turned parts from Flühs is X2CrNi18-9 (material number 1.4307, also AISI 304L). This is the low-carbon variant of 1.4301, with a maximum carbon content of 0.03 %. This property reduces the risk of intergranular corrosion, especially after welding.

What are the advantages and disadvantages of stainless steel turning parts?

The main advantages of stainless steel turned parts are the high corrosion protection of stainless steel alloys and their durability. The disadvantages of stainless steel turned parts are that they cause high tool wear during processing.

Due to the higher chromium content compared to steel, stainless steel turned parts achieve very good corrosion protection. Stainless steel is therefore extremely durable and provides reliable protection against rust, which is a particular hygienic advantage. It also has low reactivity with water or other non-aggressive chemicals.

The biggest disadvantage of stainless steel turned parts is the increased tool wear during machining. This is caused by the toughness of the material and a tendency towards work hardening and adhesion, i.e. material sticking to the cutting edge of the tool.

Suitable cutting materials, optimized cutting parameters and reliable cooling lubrication strategies are therefore required for the economical and high-quality production of stainless steel turned parts. This is the only way to minimize tool wear and ensure consistently high component quality.

How are stainless steel turned parts manufactured?

Stainless steel turned parts are manufactured by CNC turning using lathes that rotate the workpiece, which is machined by cutting and forming tools until the desired shape is achieved.

The use of CNC machines for the production of stainless steel turned parts ensures the required precision and accuracy in production. CNC-controlled production also enables consistent quality of the stainless steel turned parts, regardless of the quantity produced.

The machinability of stainless steel differs significantly depending on the alloy. To achieve optimum results, tool selection, cutting parameters and cooling lubrication are relevant. Cutting tools that are too blunt, a cutting speed that is too low or the wrong feed rate quickly lead to so-called cold hardening in stainless steel, whereby the material hardens locally and is therefore more difficult to machine.

For ferritic steels, for example, particularly wear-resistant indexable inserts are recommended in order to reduce tool wear, minimize downtime of the machine and achieve high surface qualities. To reduce burr formation on austenitic steel, the use of round indexable inserts or small adjustment angles is recommended. Duplex steel places special demands on the tools due to its high strength. Constant chip control, high-quality cooling lubricant and the setting of small rake angles help to minimize burr formation and notch wear.

During machining, heat is generated between the tool and the stainless steel workpiece. If there is insufficient cooling, the heat generated during turning is insufficiently dissipated, which leads to thermally induced dimensional deviations or deformations .

When manufacturing stainless steel turned parts, the high ductility of stainless steel must also be taken into account. Stainless steel workpieces warp easily during turning or milling and the machining tools stick together, especially at high temperatures. The use of coolants is therefore absolutely essential.

Flühs Drehtechnik has continuously optimized the production of stainless steel turned parts over the years, which is why we are able to produce precisely manufactured stainless steel turned parts in large quantities.

Customized Stainless Steel Turned Parts in Small, Medium, and Large Series

Flühs manufactures individual stainless steel turned parts in small, medium and large series.

We use computer-controlled single and multi-spindle automatic lathes for the production of stainless steel turned parts. We always use CNC automatic lathes for the production of long turned parts. Complex turned parts are manufactured on flexible turn-mill centers and production lathes in a single machining process.

In order to manufacture an individual turned part in any quantity, close consultation is first held with the customer. This involves discussing the planned area of application, the mechanical loads or environmental influences that are relevant for the stainless steel turned part. The customer's technical drawings and CAD data serve as the basis for CNC-controlled production. This results in specific tolerances to be adhered to, surface qualities and materials to be considered. If required, Flühs provides support with technical advice on materials and design optimization.

The series production of stainless steel turned parts is carried out using CNC automatic lathes. During the production process, an accompanying quality control takes place, both by the specialist personnel at the machine and by the quality assurance team. The final inspection is fully automated with image processing systems that detect deviations and sort out rejects. If necessary, post-processing takes place to deburr or clean the stainless steel.

About Us

Flühs has been specializing in turning technology for almost 100 years - since 1926. We manufacture high-quality brass and stainless steel turned parts for sanitary fittings all over the world. They are versatile and can be used in all drinking water installations. Stainless steel is also used for our own valve technology products.

Flühs Lifetime stainless steel valves are chosen for plumbing and building services whenever the requirements for hygiene, corrosion resistance, and mechanical robustness exceed what classic brass valves can provide. In potable‑water systems with high hygiene standards, for example, in laboratories or food‑processing facilities, stainless steel excels for material purity and microbiological neutrality.

Flühs Lifetime stainless steel valves are also used in regions with hard water or in systems with aggressive media.

Our formula for success remains unchanged: high‑grade materials, precise state‑of‑the‑art manufacturing processes, and an in‑house quality‑management system based on ISO 9001 and ISO 14001. Over 200 patents are the result of our power to innovate, which has been with us for around a century. Flühs is a recognized training company for technical professions with diverse specializations. We are proud that most apprentices choose to stay with us after completing their training.