Turning: Definition, History & Types

Turning is a very old machining process that is used in many industries today in its various forms. We at Flühs Drehtechnik have been involved in turning for 100 years, since 1926 to be precise.

In turning, a workpiece is clamped into an automatic lathe and set in rotation. Tools are used to remove material from the surface of the workpiece until it has the desired shape. This process is called machining, and the finished part is a turned part.

The basic operating principle of turning has remained the same throughout history; only the degree of automation and the machine technology have changed.

There are various turning processes that are used depending on the requirements and the shape of the workpiece.

This article answers the question of what turning is, describes the history of turning, and describes different types of turning.

What is turning?

According to DIN 8580, turning is a machining process for the production of rotationally symmetrical components, which belongs to the group of separating processes. During turning, the workpiece rotates around its own axis while being machined by a stationary tool. Cutting, grooving, and forming tools, among others, are used during the machining process.

Unlike milling, where the tool rotates and the workpiece remains fixed, turning involves the workpiece itself rotating.

The result of the turning process is a turned part. Turned parts are important functional components in various industries, for example screws, nuts, sleeves, axles, and other connecting elements for machine construction, medical technology, the sanitary industry, and electrical engineering.

Typical materials used in turning are metallic materials such as steel, cast iron, stainless steel, and non-ferrous metals (NF metals) such as aluminum and copper alloys such as red brass or brass, which are used in the mechanical engineering industry, sanitary and building services applications, and the automotive industry, among others. Metals that are difficult to machine include titanium and nickel-based alloys, which are often used in medical technology due to their biocompatibility. Plastic is also a turnable material that is used in numerous industries, such as chemical, process, and building technology.

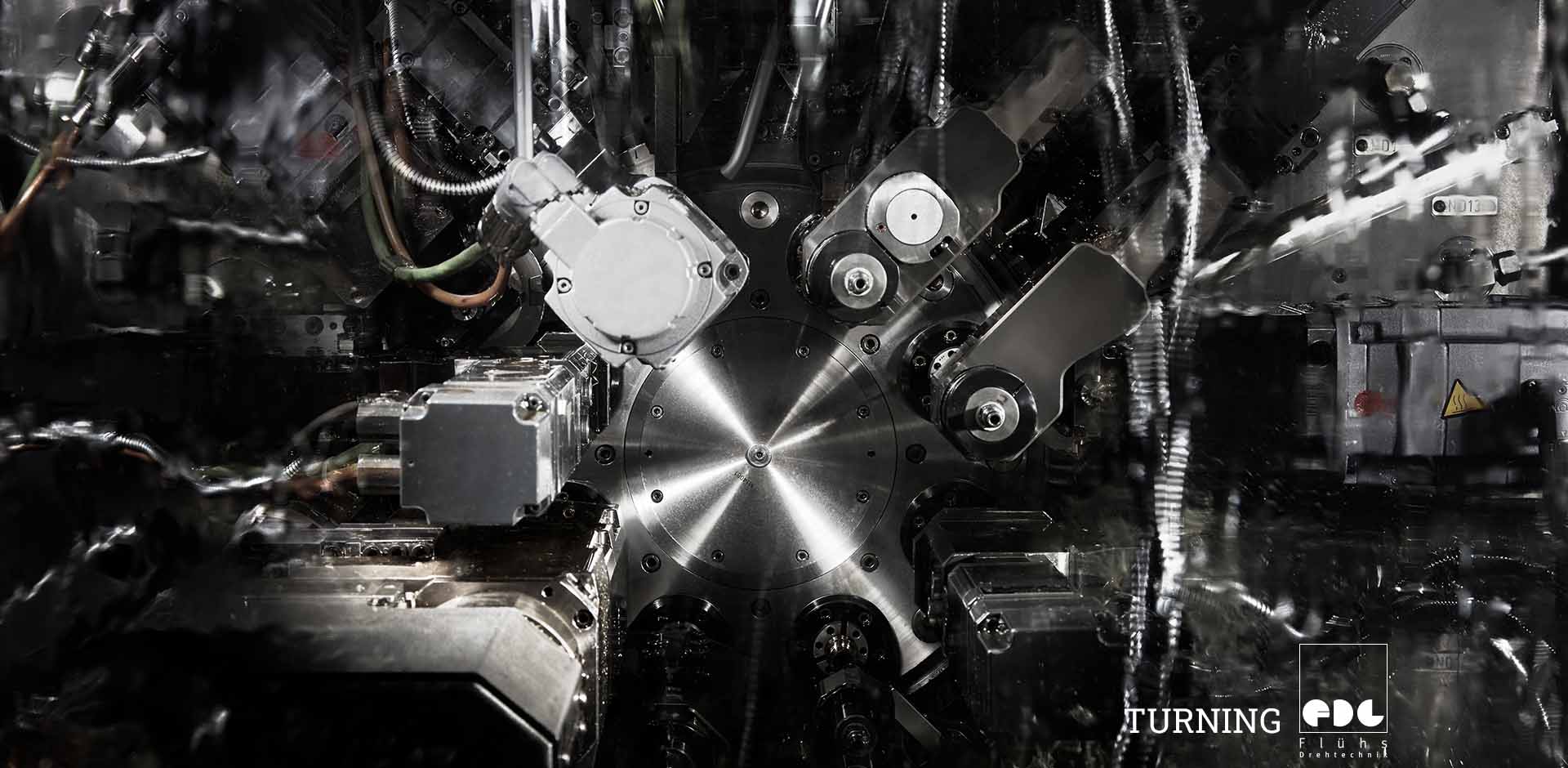

Lathes are used for turning. A lathe is a machine tool that uses sharp-edged tools such as turning tools or indexable inserts to remove material from the rotating workpiece layer by layer.

There are conventional, automated, and CNC (computer numerical control) lathes. CNC automatic lathes dominate series production today because their high degree of automation ensures consistently high precision and repeat accuracy.

Lathe technology has changed significantly over the course of history, even though the operating principle of turning has remained the same.

History of Turning

The history of turning dates back to the last millennium BC. Turning developed from drilling and is one of the oldest known manufacturing processes.

The first lathes were hand-operated devices that were continuously perfected over the course of history, for example, by Leonardo da Vinci, who added a treadle drive, and Jacques Besson (16th century), who introduced a mechanical feed using weights.

Since around 1760, lathes have featured central elements of modern turning technology, including a leading spindle and change gears. Henry Maudslay (1771–1831) in particular is considered a pioneer of the modern lathe. His invention around 1797 laid the foundation for industrial metalworking. The first cam-controlled automatic lathe was patented in 1873. The Swiss engineer Christoph Gildemeister developed this type of machine. The invention of the swiss-type automatic lathe with a movable headstock around 1880 is attributed to Jakob Schweizer, a watchmaker from Biel. This is where the term “Swiss turning” comes from.

In 1950, John Parsons developed NC (numerical control) technology at the Massachusetts Institute of Technology in Cambridge (USA). NC technology uses punch cards to control the machine. In 1978, the transition to CNC (computer numerical control) technology took place. CNC technology makes it possible to automate the entire manufacturing process, from clamping the workpiece to the turning process to quality control and post-processing.

Despite all the technological advances, the basic principle of the turning process has remained the same over the centuries.

What are the different types of turning?

According to DIN 8589 (Manufacturing Processes Chip Removal - Turning), there are 6 different types of turning: face turning, straight turning, thread turning, roll turning, profile turning, and contour turning.

-

Face Turning

Face turning produces a flat surface at a 90° angle to the axis of rotation, for example, on the end faces of the workpiece. The turning tool moves in the axial direction (perpendicular to the axis of rotation of the workpiece). Face turning is used to adjust lengths (by cutting off the bar material) and to produce sealing and flat surfaces.

-

Straight Turning

Straight turning produces a cylindrical or conical surface that is coaxial with the axis of rotation of the workpiece. The tool moves in a longitudinal direction (parallel to the axis of rotation). A distinction is made between longitudinal turning and cross turning. In longitudinal turning, the tool moves along the axis of rotation. In cross turning, the tool moves radially (inward or outward). Typical applications of straight turning are the production of shafts, sleeves, and bolts, for external and internal turning, and for roughing.

-

Thread Turning

Thread turning produces helical geometries, typically threads. The tool performs a controlled feed movement in relation to the workpiece rotation. The process is CNC-controlled or mechanically synchronized. Profile tools are used that precisely replicate the thread profile. Typical applications of thread turning are external threads and internal threads as well as spindles, screws, and nuts.

-

Roll Turning

Roll turning produces toothed or helical profiles, for example in gear wheels or threaded spindles. The tool performs a combined feed and rolling motion, whereby the profile is created by rolling. It is similar to gear hobbing, but is one of the processes with a geometrically defined cutting edge. Typical applications of roll turning are worm shafts and gear teeth.

-

Profile Turning

In profile turning, the shape of the tool profile is transferred directly to the workpiece. The tool has a fixed contour that acts on the rotating workpiece as it moves. Profile turning can only be performed with rotationally symmetrical profiles, as the tool is rigid. Typical applications include the machining of notches, grooves and other defined shapes.

-

Contour Turning

Contour turning uses a CNC-controlled feed motion to create non-linear or complex geometries. The tool follows a precisely programmed path. The advantage of form turning is that it is suitable for producing free forms without special profile tools. Typical applications include the production of concave, convex, or free-form workpiece contours and complex geometries.

Flühs Drehtechnik uses all common turning processes to manufacture high-quality turned parts in small, medium, and large series.

Turning at Flühs Drehtechnik

Turning at Flühs Drehtechnik has a long tradition. Flühs was founded in 1926 as a turned parts manufacturer. Since then, the company has grown organically and now has a production area of approximately 20,000 m² and over 130 cam-controlled and CNC-operated lathes. More than 400 employees work at Flühs in production, assembly, administration, and research and development.

Flühs primarily processes various (lead-free) brass alloys, which are easy to machine and ideal for use in the sanitary sector. Over the years, Flühs has developed into a successful manufacturer of valve and system technology, supplying the largest companies in the sanitary industry and selling its products in more than 50 countries.

Flühs' R&D department works with customers to develop customized assemblies and optimize assembly techniques to enable efficient workflows.

Our quality assurance is based on DIN ISO 9001 and ISO 14001. We carry out quality control during series production and a final inspection, using state-of-the-art technology (including high-speed cameras and coordinate measuring machines). This ensures the highest precision in the turned parts we produce.

Flühs's machinery features state-of-the-art technology in CNC machining. This enables us to produce high-quality turned parts in series in any quantity.

Flühs has more than 200 patents. Innovation has always been and continues to be a driving force behind our products, which are market leaders in the field of valve technology.

Turning is at the heart of Flühs' manufacturing process and forms the basis of our high-quality components for building technology.